Concrete protection system

The idea Higly resistant material for multigrade use + immediate serviceability by avoiding setting and waiting times.

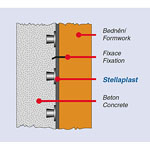

For Stellaplast we use weld-able synthetics mechanically fixed onto the substrate by means of knobs. Work can start immediately after the substrate has obtained the neccessary structural strength.Thus waiting times formerly occured by setting of the concrete, preparing and curing of materials can be avoided.

Relining

Stellaplast is applied in form of prefabricated parts as „lost formwork" and embedded directly into the concrete. In case of prefabricated concrete parts, this operational sequence is already effected by the respective manufacturer.

After having removed the casings, the abutting connections and the holes of the fixations are to be tightly welded. The smooth and prompt execution can be safeguarded by an exact planning and using large sized refabricated parts.

Reconstruction

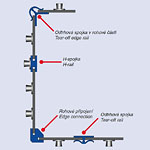

We merely install Stellaplast in front of the existing lining. By means of Didier’s mounting systém a cavity is provided which is filled with a special grouting compoud. This systém is to be supported and braced carefully, thus preserving its shape. Subsequently, aqbutments and transitions are tightly welded.

Stellaplast - Inserts

Prefabricated parts are an important component of the Stellaplast system. By using prefabricated parts the welding work at site can be minimized thus increasing safety and reducing working time.

Stellaplast properties

| Property | Unit | Method of testing | grey * | black * |

|---|---|---|---|---|

| Density | g/cm3 | DIN 53479 / ISO R 1183 | ca. 0,915 | ca. 0,96 |

| Yield stress | N/mm3 | DIN 53455 / ISO DIS 527 | >= 33 | <= 22 |

| Elongation at tear | % | DIN 53455 / ISO DIS 527 | >= 800 | <= 800 |

| Impact strength | k/m2 | DIN 53453 / ISO 179 | kein Bruch bei / no fracture at +23 °C |

kein Bruch bei / no fracture at +23 °C |

| Indentation hardness, ball | N/mm2 | DIN 53456 / ISO 2039 | >= 64 | <= 40 |

| Modulus of elasticity | N/mm2 | DIN 53457 | >= 1.200 | |

| Vicat softening point | °C | DIN 53460 / ISO 306 | >= 87 | <= 67 |

| Shape perfomance to heat A/B | °C | DIN 53461 / ISO R 75 | ca. 59/96 | |

| Linear coefficient of expansion | K-1(1/°C) | gemessen zwischen 20 und 30 °C measured between 20 und 30 °C |

ca. 1,8 x 10-4 | ca. 1,7 x 10-4 |

| Psychologically harmless | Empfehlungen/ recommended by des BGA |

yes | yes | |

| Behavior in fire | DIN 4102 | B 2 | B 2 |

* Standard qualities; nearly all others types of weldable synthetic materials are available

The chemical resistance of Stellaplast material is extensive. For this reason, we cannot give details here. However, we are prepared to submit our resistance tables for your specific case of requrement or to examine together with your usability of Stellaplast.